Understanding the Significance of Core Drilling Equipment in Modern Construction Projects

Core drilling devices is vital in contemporary building, promoting exact openings for various systems. This equipment consists of sophisticated devices like diamond and carbide-tipped drills, which permit effective sampling and installment. Investing in high-grade devices not just boosts performance however also enhances safety and security on-site. Nonetheless, recognizing the complete implications of these devices goes beyond mere performance. The details of their applications and future trends warrant additional exploration.

Sorts Of Core Boring Equipment

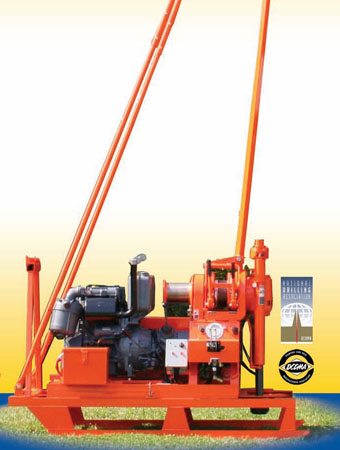

When exploring the different sorts of core exploration devices, it becomes apparent that each tool is made for specific applications and materials. Core drills come in several types, including ruby core drills, which are ideal for difficult materials like concrete and stone as a result of their accuracy and resilience. One more type is the carbide-tipped core drill, matched for softer substratums such as asphalt and brick. Additionally, the rotary drill is frequently used for basic purposes, offering versatility throughout various projects.

Mobile core exploration makers, preferred for their wheelchair, enable on-site procedures in confined rooms. Alternatively, larger, stationary gears are made use of for extensive drilling tasks, commonly in industrial settings. Each tool is matched by numerous drill bits, customized to the hardness and make-up of the product being passed through - Core Drilling Equipment. Recognizing these differences is essential for picking the ideal devices for efficient core exploration in building and construction jobs

Applications of Core Exploration in Construction

Core boring plays a necessary function in various building and construction applications, as it enables efficient and exact product elimination in a range of jobs. Among the key applications is in the installation of plumbing and electrical systems, where exact openings are needed for pipes and conduits to go through wall surfaces and floorings. Additionally, core drilling is utilized for sampling functions, making it possible for engineers to extract cylindrical samples of concrete or dirt for screening and evaluation.

An additional significant use of core exploration remains in the production of support points, which are required for safeguarding architectural aspects such as beam of lights and columns. It is additionally used in remodeling existing structures, enabling alterations without endangering the honesty of bordering materials. Moreover, core boring helps with the setup of HVAC systems by supplying openings for ductwork. Generally, these applications show core boring's essential contribution to contemporary building and construction performance and precision.

Advantages of Spending in High Quality Tools

Investing in quality devices is necessary for making sure optimal performance and longevity in building tasks. Top quality core drilling equipment supplies remarkable precision, allowing service providers to attain precise results while lessening material waste. These devices are created to withstand extensive use, causing lower upkeep expenses and longer lifespans. Additionally, trusted devices can significantly boost productivity, allowing groups to finish tasks a lot more efficiently and meet job deadlines.

An additional advantage is that top quality tools typically feature improved safety and security features, offering operators with much better control and reducing the risk of accidents. Furthermore, spending in reliable brand names can lead to far better customer assistance and service warranty solutions, ensuring that any concerns can be dealt with promptly. Ultimately, the upfront investment in high quality tools settles in the lengthy run, causing increased total project efficiency, decreased downtime, and greater customer satisfaction with superior craftsmanship.

Safety Factors To Consider When Using Core Boring Tools

Guaranteeing security while using core drilling devices is vital to stop crashes and injuries on building websites. Operators should use ideal individual safety devices (PPE), including headgears, handwear covers, and eye defense, to minimize dangers related to flying debris and devices malfunctions. Appropriate training is crucial, as it equips employees with the understanding to take care of equipment safely, identify possible hazards, and carry out emergency treatments.

Normal maintenance and inspection of core boring devices can help determine deterioration, reducing the likelihood of devices failure during procedure. Additionally, keeping a well organized and tidy job location lessens stumbling dangers and warranties that workers can operate equipment securely. Communication among employee is essential, as it promotes a culture of safety and security where every person knows their surroundings and potential dangers. By focusing on these security considerations, building and construction tasks can operate extra successfully while safeguarding the wellness of all personnel included.

Future Trends in Core Exploration Technology

Innovations in core boring modern technology are positioned to change the building market, building on the precaution already highlighted in current methods. Emerging patterns include the integration of robotics and automation, which intend to boost accuracy and efficiency while reducing human error. Additionally, the development of lightweight, mobile tools is making core drilling much more obtainable, permitting easier transportation and arrangement on varied task sites.

Additionally, developments in ruby drill little bit innovation are leading to longer-lasting tools that can puncture different materials with reduced downtime. The unification of information analytics and IoT innovation is additionally anticipated to enhance monitoring and upkeep, making certain perfect efficiency and decreasing operational costs. In enhancement, sustainable techniques are getting grip, with producers concentrating on eco-friendly materials and energy-efficient here are the findings machinery. Collectively, these fads signify a transformative change, guaranteeing to enhance efficiency while focusing on safety and ecological duty in core boring procedures.

Frequently Asked Questions

How Do I Pick the Right Core Exploration Tools for My Project?

To select you could try these out the right core boring equipment, one ought to assess task specifications, figure out the material type, assess the called for hole size, and think about the tools's power resource and portability to ensure peak efficiency and efficiency.

What Is the Typical Lifespan of Core Drilling Equipment?

The ordinary life-span of core exploration devices commonly varies from five to 10 years, depending upon use intensity, upkeep methods, and product kinds. Proper care can considerably prolong their operational long life, improving general effectiveness.

Can Core Drilling Devices Be Leased As Opposed To Purchased?

Yes, core boring devices can be rented out rather than purchased. Lots of construction firms choose rentals to lower expenses and avoid upkeep duties, particularly for temporary jobs where purchasing would be unnecessary or impractical.

What Maintenance Is Required for Core Boring Machines?

Exactly How Does Core Exploration Impact Surrounding Structures Throughout a Job?

Core exploration can impact surrounding frameworks by causing vibrations and minor shifts in foundation security. Proper strategies and tools are necessary to minimize these effects, guaranteeing safety and security and integrity of adjacent structures during building activities.

Core exploration devices is necessary in contemporary building, promoting specific openings for different systems. When checking out the numerous kinds of core exploration devices, it becomes evident that each tool is created for specific applications and materials. Core drills come in a number of types, consisting of diamond core drills, which are optimal for that site difficult products like concrete and rock due to their accuracy and sturdiness. Guaranteeing safety and security while utilizing core exploration tools is paramount to preventing accidents and injuries on building and construction websites - Core Drilling Equipment. Normal upkeep and assessment of core boring tools can help recognize wear and tear, decreasing the chance of devices failing throughout procedure